|

General

Description of Valves

This unique family of valves is intended to be used as safety devices

in Intermediate Bulk Containers. The valve body features 2 inch

external threads and is designed to be torqued into a spin weld

fitting or a tank lid for a leak-tight installation. (Recomended

spin weld fitting, Part Number 58HD)

|

Technical

Specifications

Materials of Construction:

- Valve Bodies

& Plungers - High Density Polyethylene (HDPE).

- O-rings -

Nitrile [Buna] or Fluorocarbon [Viton]

- Other O-ring

materials can be used given sufficient lead time.

- Springs -

Zinc-plated Spring Steel and Stainless Steel.

- Hastelloy

C can be used given sufficient lead time.

|

|

Functional

Operation

752 - Vacuum Breaker only, allows outside air to enter tank. Applications

include chemical spraying or rapid pump out of tank. Protects tank

from buckling. Tractor Test Certified. Venting with no spillage.

- Vacuum pressure

to open 0.5 psi differential

|

|

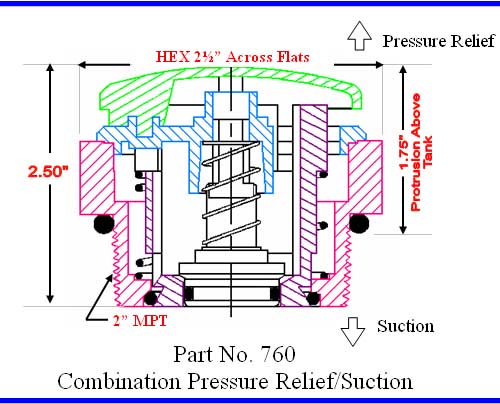

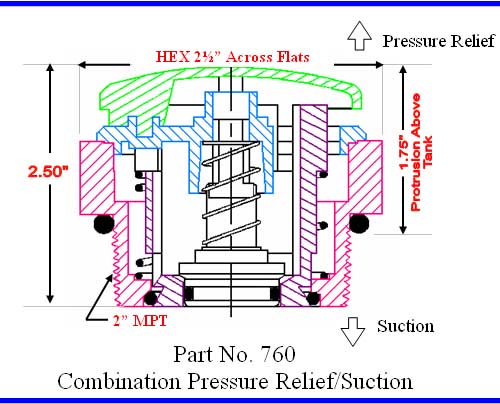

760 - Combination

Pressure Relief & Vacuum Breaker. Provides both pressure relief

and vacuum breaking with in a single housing. "Acts as a 2-way

breather." Similar in design to the #760 DOT, but releases

at lower pressure and has less stringent leak requirements.

- Vacuum pressure

to open 0.5 psi differential

- Pressure

relief 1.5 psi

|

|

760 DOT -

Combination Pressure Relief & Vacuum Breaker. Currently used

for DOT certified IBC's.

- Vacuum pressure

to open 0.5 psi differential

- No detectable

leak 3.0 psi

- Pressure

relief 4.0 psi

|

|

Additional

Features:

A seal is formed

at the internal tank surface, minimizing the contact of product

vapor with the spring surfaces.

Pre-set factory pressure and suction relief levels. Once set, the

unit is permanently joined by ultrasonic welding, preventing alteration

of the specified pressure venting levels.

Machined sealing surfaces.

Dome-shaped cover to prevent ice and snow build-up from interfering

with valve function.

Valve material contains a full complement of Environmental Stress

Additives (ESA) including Ultraviolet (UV) to prevent weathering.

|

Part

No |

Description

|

O'Ring

Seals |

#752-B

|

Vacuum

Breaker |

Nitrile

[Buna-N] |

#752-V |

Vacuum

Breaker |

Fluorocarbon

[Viton] |

#760 |

Combination

Valve |

Nitrile

[Buna-N] |

#760

DOT-B |

Combination

Valve |

Nitrile

[Buna-N] |

#760

DOT-V |

Combination

Valve |

Fluorocarbon

[Viton] |

|

VENT

VALVE - SUCTION RELIEF |

Part

No |

CRACKING

PRESSURE |

Description |

752-B

|

Open

0.5 PSI Differential |

Vacuum

Breaker - only, with Nitrile [Buna-N] seals (vacuum pressure

to open < 0.5 psi) |

752-V |

Open

0.5 PSI Differential |

Vacuum

Breaker - only, with Viton seals (vacuum pressure to open

< 0.5 psi) |

|

|

|

|

VENT

VALVE - COMBINATION PRESSURE & SUCTION RELIEF

|

Part

No |

CRACKING

PRESSURE |

Description |

760 |

Open

0.5 PSI Differential Relief 1.5 PSI |

Combination

Pressure/Vacuum with Nitrile [Buna-N] seals |

760

DOT-B |

Open

< 0.5 PSI Differential

Relief

4.0 PSI

|

Combination

Pressure/Vacuum with Nitrile [Buna-N] seals |

760

DOT-V |

Open

< 0.5 PSI Differential

Relief

4.0 PSI

|

Combination

Pressure/Vacuum with Viton seals

|

|

![]() ACCEPTED

ACCEPTED